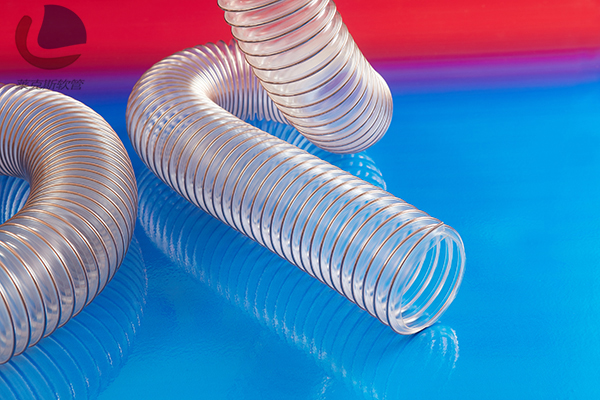

Food grade steel wire hose LKE605

Application: Widely used in suction applications, where there are worn solids such as dust, powder, fiber and debris, active media such as oil, steam and solder smoke and industrial dust removal and suction.

Properties: Very fluid properties, resistance to microbiology and hydrolysis, good chemical and mineral oil resistance; Good resistance to ultraviolet and ozone;

High tensile strength and tear strength, high scalability and compression ratio 4:1, small bending radius, not easy to knot; Food grade compliance: FDA 21 CFR 177.2600 and 178.2010, EC Regulation 2002/72/EC, in compliance with RoHS regulations; It can discharge static electricity and is grounded by helical wire.

Structure: tube wall coated with elastic steel wire, ribbon extrusion, wall thickness of about 0.4 mm;

Raw material: tube wall: special polyether-polyurethane, spiral wire: elastic steel wire;

Temperature range: about -40°C to +125°C up to +150°C for a short time

Product specifications:

|

I.D |

O.D |

OP.pressure |

Bend radius ( Middle of hose) |

Weight |

Length |

Item NO |

|

|

positive pressure |

negative pressure |

||||||

|

mm |

mm |

bar |

bar |

mm |

Kg/m |

m |

|

|

38 |

46 |

0.9 |

0.3 |

46 |

0.17 |

10 |

LKE-00605-0038 |

|

40 |

48 |

0.865 |

0.28 |

48 |

0.19 |

10 |

LKE-00605-0040 |

|

45 |

53 |

0.765 |

0.265 |

53 |

0.23 |

10 |

LKE-00605-0045 |

|

50 |

58 |

0.695 |

0.24 |

58 |

0.27 |

10 |

LKE-00605-0050 |

|

51 |

59 |

0.68 |

0.24 |

59 |

0.29 |

10 |

LKE-00605-0051 |

|

60 |

68 |

0.58 |

0.19 |

68 |

0.31 |

10 |

LKE-00605-0060 |

|

63 |

71 |

0.55 |

0.18 |

71 |

0.33 |

10 |

LKE-00605-0063 |

|

65 |

73 |

0.535 |

0.17 |

73 |

0.34 |

10 |

LKE-00605-0065 |

|

70 |

78 |

0.495 |

0.14 |

78 |

0.39 |

10 |

LKE-00605-0070 |

|

75 |

83 |

0.465 |

0.13 |

83 |

0.41 |

10 |

LKE-00605-0075 |

|

80 |

88 |

0.435 |

0.12 |

88 |

0.44 |

10 |

LKE-00605-0080 |

|

90 |

98 |

0.385 |

0.105 |

98 |

0.49 |

10 |

LKE-00605-0090 |

|

100 |

108 |

0.35 |

0.08 |

108 |

0.52 |

10 |

LKE-00605-0100 |

|

102 |

110 |

0.34 |

0.08 |

110 |

0.53 |

10 |

LKE-00605-0102 |

|

110 |

118 |

0.32 |

0.075 |

118 |

0.57 |

10 |

LKE-00605-0110 |

|

115 |

123 |

0.3 |

0.07 |

123 |

0.59 |

10 |

LKE-00605-0115 |

|

120 |

128 |

0.29 |

0.07 |

128 |

0.62 |

10 |

LKE-00605-0120 |

|

125 |

133 |

0.28 |

0.055 |

133 |

0.64 |

10 |

LKE-00605-0125 |

|

127 |

135 |

0.275 |

0.055 |

135 |

0.65 |

10 |

LKE-00605-0127 |

|

130 |

138 |

0.27 |

0.055 |

138 |

0.68 |

10 |

LKE-00605-0130 |

|

140 |

148 |

0.25 |

0.05 |

148 |

0.72 |

10 |

LKE-00605-0140 |

|

150 |

158 |

0.175 |

0.045 |

158 |

0.74 |

10 |

LKE-00605-0150 |

|

152 |

160 |

0.17 |

0.045 |

160 |

0.78 |

10 |

LKE-00605-0152 |

|

160 |

168 |

0.165 |

0.04 |

168 |

0.82 |

10 |

LKE-00605-0160 |

|

170 |

178 |

0.155 |

0.035 |

178 |

0.86 |

10 |

LKE-00605-0170 |

|

175 |

183 |

0.15 |

0.035 |

183 |

0.88 |

10 |

LKE-00605-0175 |

|

180 |

188 |

0.145 |

0.03 |

188 |

0.90 |

10 |

LKE-00605-0180 |

|

200 |

208 |

0.13 |

0.03 |

208 |

0.96 |

10 |

LKE-00605-0200 |

|

203 |

211 |

0.13 |

0.03 |

211 |

0.98 |

10 |

LKE-00605-0203 |

|

225 |

233 |

0.115 |

0.02 |

233 |

1.08 |

10 |

LKE-00605-0225 |

|

250 |

258 |

0.105 |

0.015 |

258 |

1.20 |

10 |

LKE-00605-0250 |

|

275 |

283 |

0.095 |

0.01 |

283 |

1.35 |

10 |

LKE-00605-0275 |

|

280 |

288 |

0.095 |

0.01 |

288 |

1.4 |

10 |

LKE-00605-0280 |

|

300 |

309 |

0.09 |

0.01 |

309 |

1.57 |

10 |

LKE-00605-0300 |

|

325 |

334 |

0.08 |

0.010 |

334 |

1.7 |

10 |

LKE-00605-0325 |

|

350 |

359 |

0.075 |

0.005 |

359 |

1.83 |

10 |

LKE-00605-0350 |

|

400 |

409 |

0.065 |

0.005 |

409 |

2.08 |

10 |

LKE-00605-0400 |

|

450 |

459 |

0.06 |

0.005 |

459 |

2.34 |

10 |

LKE-00605-0450 |

|

500 |

509 |

0.055 |

0.005 |

509 |

2.6 |

10 |

LKE-00605-0500 |

官方公众号

官方公众号