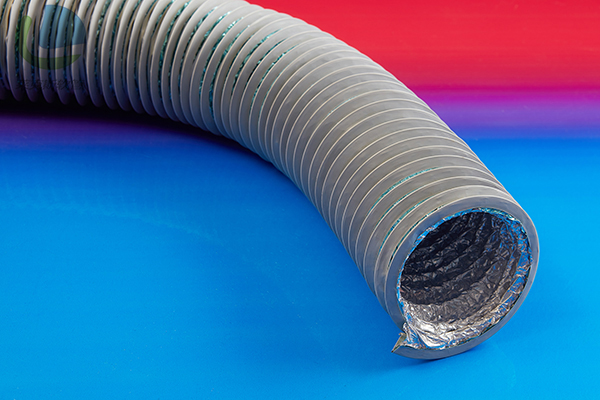

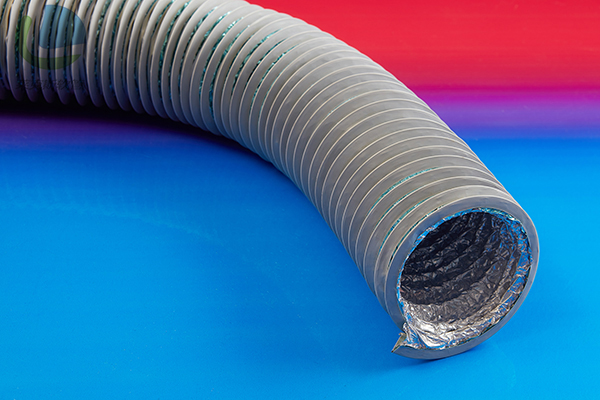

Material: PVC with internal aluminum foil coating and embedded steel wire.

Application: Suitable for medium/low-pressure central air conditioning and ventilation systems.

Product Features:

-

Manufactured by winding PVC film over steel wire, with internal anti-corrosion film.

-

Temperature range: 0°C–80°C; maximum airflow velocity: 30m/s; maximum operating pressure: 2500Pa.

-

Ideal for exhaust systems handling corrosive gases (e.g., acids, alkalis).

Advantages:

-

Lightweight, high strength—no need for angle iron brackets.

-

Flexible bending without rigid elbows, reducing airflow resistance.

-

Integrated molding minimizes air leakage.

-

Resistant to corrosive gases, aging, static electricity, chemical fumes, fire, and abrasion.

-

Easy installation, compatible with ventilation fans, range hoods, etc.

Applications:

-

Mechanical equipment (dryers, ovens, injection molding machines, high-temperature ironing).

-

Factories, vehicle exhaust, bathrooms, electronics plants, sewers, shipyards, refrigeration, environmental protection.

-

Exhaust of smoke, moisture, dust, high-temperature gases, and powder ventilation.

Key Features:

-

Ventilation/exhaust for bathrooms, dryers, range hoods, fireplaces.

-

High resistance to corrosion and microbial growth.

-

Flexible installation—easily connects to any desired position, especially in prefabricated duct systems, with superior bending flexibility.

-

Quick/economical correction of component misalignment.

-

Low friction loss and air leakage when properly installed.

-

Cost-effective transportation and storage.

Installation Method:

-

Slide clamps onto the duct (or use air conditioning ties).

-

Peel back 1–2 layers of steel wire.

-

Wrap exposed wire around the check valve/outlet flange and secure with aluminum foil tape.

-

Seal the peeled area with full-length aluminum foil tape or waterproof tape to prevent leaks.

-

Tighten clamps/ties at the outlet for final fixation.

Customization: Other specifications, sizes, and special requirements available upon request.

官方公众号

官方公众号